What Does an EGR ...

Aug 09, 2025

The crankcase ventilation (CCV) system on the 6.7L Cummins plays a vital role in managing blow-by gases and maintaining proper crankcase pressure. However, the factory design often results in excessive pressure build-up, oil consumption and turbo contamination. This article details actual pressure testing of a stock CCV system, identifies key restriction points, and explains why CCV redirection or PCV redirection is often necessary for optimal engine performance and longevity. Why Test CCV System Pressure? Excessive crankcase pressure can cause: · Oil leaks (seals, gaskets, turbo feed lines) · Increased oil consumption (blow-by carrying oil into intake) · Turbocharger contamination (oil coking on compressor wheel) · Reduced engine efficiency (higher crankcase pressure = more parasitic loss) By measuring pressure at different points in the system, we can pinpoint where restrictions occur and determine the best solution—whether that’s a CCV reroute kit, a catch can, or a complete redesign. Testing Methodology We conducted pressure tests on a stock 6.7L Cummins using: · Digital manometer (measuring in inches of water column, "H₂O) · Pressure taps at critical locations: o Valve cover outlet (pre-CCV restriction) o Post-CCV hose (before turbo inlet) o Crankcase dipstick tube (baseline pressure) Tests were performed at:✔ Idle (700 RPM)✔ Mid-load (2,000 RPM, light throttle)✔ High-load (WOT, 3,000+ RPM) Key Findings: Where the Stock CCV System Fails 1. Excessive Crankcase Pressure at Higher RPM · Idle: ~1.5" H₂O (acceptable) · 2,000 RPM: ~4.2" H₂O (approaching problematic) · WOT: 8-10" H₂O (far beyond ideal) Why It Matters: · Pressures above 4-5" H₂O can force oil past seals and into the intake. · At WOT, the stock system cannot evacuate blow-by efficiently. 2. Major Restriction: Factory CCV "Rooster Comb" Baffle The stock Cummins CCV system uses a "rooster comb" baffle inside the valve cover to separate oil from blow-by gases. Testing revealed: · Pressure drop across baffle: ~3.5" H₂O at high RPM · Oil carryover: Significant mist still reaches the turbo inlet Problem: The factory baffle is too restrictive and doesn’t separate oil effectively. 3. Turbo Inlet Contamination Risk · Post-CCV testing showed oil mist accumulation in the intake piping. · Over time, this leads to turbo coking and intercooler clogging. The Solution: CCV Reroute or Performance Baffle Upgrade Since the stock system is restrictive and inefficient, there are two proven fixes: Option 1: Full CCV Reroute (Vented or Catch Can) · Eliminates intake contamination by venting to atmosphere or a catch can. · Reduces crankcase pressure to safe levels (<3" H₂O at all RPMs). · Best for modified/high-performance engines where blow-by is increased. Option 2: High-Flow Baffle Upgrade · Replaces restrictive "rooster comb" with a better-flowing design. · Improves oil separation while maintaining emissions compliance. · Good for stock/near-stock trucks where rerouting isn’t desired. Performance Gains from a Proper CCV Solution ✔ Reduced oil consumption (less blow-by oil loss)✔ Cleaner turbo & intercooler (no more oil coking)✔ Longer engine life (less pressure on seals/gaskets)✔ Better throttle response (reduced crankcase pumping losses) Upgrade Your CCV System Today If your 6.7L Cummins is suffering from excessive crankcase pressure or oil consumption, a CCV reroute kit is the proven solution. Check out our high-performance CCV/PCV Reroute Kits to optimize your engine’s breathing and reliability.

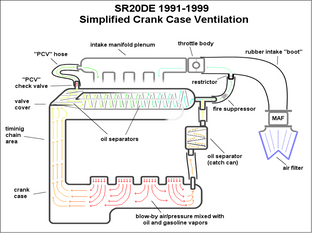

The crankcase ventilation (CCV) system, also known as the positive crankcase ventilation (PCV) system, plays a vital role in maintaining engine health by managing blow-by gases. However, poor design can result in excessive oil consumption, turbo contamination and reduced engine efficiency. This article explores how Venturi effect dynamics and baffle engineering affect oil separation, and how CCV redirection or PCV redirection can optimize performance in modern diesel engines. The Role of the CCV/PCV System The CCV system prevents pressure build-up in the crankcase by rerouting blow-by gases back into the intake for combustion. However, if these gases are not properly controlled they can lead to oil mist, which: · Coat turbocharger wheels, reducing efficiency · Clog intercoolers, increasing intake air temperatures · Contaminate sensors, causing drivability issues Venturi Effect: How It Enhances Oil Separation Many high-performance CCV systems take advantage of the Venturi effect – a fluid dynamics principle in which the velocity of a gas increases as it passes through a constricted section, causing a reduction in pressure. Key Benefits of Venturi-Based CCV Systems Improved Oil Mist Capture – The low-pressure zone helps separate oil droplets from blow-by gases.Reduced Turbo Contamination – Less oil ingestion means cleaner compressor wheels and intercoolersLower Crankcase Pressure – Efficient evacuation minimizes oil leaks and seal failures. Baffle Design: The Unsung Hero of Oil Separation An effective baffle system inside the valve cover or CCV housing ensures that oil droplets are trapped before entering the intake. Critical Baffle Design Features · Multi-Stage Filtration – Mesh screens, centrifugal separators, and impact surfaces maximize oil capture. · Drainback Channels – Collected oil must return efficiently to the crankcase to prevent pooling. · Heat Resistance – High-quality materials prevent warping under extreme temperatures. Why a CCV Reroute or PCV Reroute is Often Necessary Factory CCV systems are often undersized or poorly routed, leading to: · Excessive oil consumption · Turbo oil coking · EGR and intake clogging A high-quality CCV reroute kit solves these issues by:Relocating the vent path (e.g., to atmosphere or a catch can)Incorporating advanced baffling for superior oil separationReducing intake tract contamination Performance & Longevity Benefits of an Optimized CCV System · Cleaner Turbo & Intercooler – Prevents oil buildup that restricts airflow. · Stable Crankcase Pressure – Reduces risk of leaks and seal failures. · Improved Engine Efficiency – Less oil burn means better combustion consistency. Upgrade Your CCV System Today If your engine suffers from excessive oil consumption or turbo contamination, a PCV/CCV reroute could be the solution. Check out our selection of high-performance CCV/PCV Reroute Kits to optimize your engine’s breathing.

Modern diesel engines are marvels of power, durability, and engineering efficiency. However, as emissions regulations have evolved, so too have the systems designed to meet these increasingly strict environmental standards. One such system is the Crankcase Ventilation (CCV) system, which plays a crucial role in managing internal engine pressure and emissions. Over time, however, this system can contribute to unwanted engine complications that reduce performance, increase maintenance, and affect long-term reliability. As a result, many diesel owners consider installing a CCV reroute as a practical upgrade. This article explores what a CCV reroute does, why it is often installed, and how it benefits diesel engines. Understanding the CCV System in Diesel Engines The Crankcase Ventilation (CCV) system is designed to relieve internal pressure caused by combustion gases that leak past the piston rings and enter the crankcase. These gases, commonly referred to as blow-by gases, are composed of air, unburned fuel, water vapor, and oil mist. Left unchecked, these gases would build up inside the engine and could cause seals to fail or gaskets to leak. To manage this, the CCV system reroutes these gases from the crankcase back into the intake system, where they are re-burned in the combustion chamber. While this reduces hydrocarbon emissions and aligns with federal regulations, it introduces oil vapors and contaminants directly into the engine’s intake tract, leading to several performance and maintenance concerns over time. What Is a CCV Reroute? A CCV reroute modifies the factory crankcase ventilation pathway. Instead of routing the blow-by gases back into the intake system, the CCV reroute redirects them to a separate venting location—often to the atmosphere or through a catch can system. This redirection prevents oil vapors from re-entering the intake manifold and mixing with fuel and air during combustion. The result is a cleaner intake system, reduced carbon buildup, and better overall airflow to the engine. The reroute can be installed using a series of hoses, fittings, and often a sealed filter or catch can that collects the oil vapor instead of allowing it to recirculate. Key Benefits of a CCV Reroute Installing a CCV reroute offers a wide range of advantages, especially for diesel trucks used in demanding applications such as towing, hauling, or performance modifications. Below are the most significant benefits associated with rerouting the CCV system. 1. Cleaner Intake System One of the most immediate and visible benefits of a CCV reroute is the dramatic reduction in oil contamination within the intake manifold and intercooler system. When oil vapor is introduced into the intake, it sticks to internal surfaces and combines with soot from the Exhaust Gas Recirculation (EGR) system. This creates a thick, sticky sludge that coats intake runners, turbocharger fins, and charge pipes. By redirecting oil-laden vapors away from the intake, a CCV reroute helps maintain cleaner intake components, which promotes better airflow and more efficient combustion. 2. Reduced Turbocharger Contamination Turbochargers rely on precise air dynamics and extremely tight tolerances. When oil vapors enter the intake and pass through the turbocharger, they can create residue on the turbine and compressor wheels. Over time, this buildup restricts the turbo’s efficiency, slows spool-up, and may lead to premature bearing wear or seal failure. A CCV reroute helps reduce these issues by preventing oil vapor from ever reaching the turbo, protecting this critical component and extending its service life. 3. Improved Engine Performance and Efficiency Cleaner air entering the combustion chamber leads to more consistent combustion, which enhances throttle response and power output. Additionally, with fewer contaminants introduced into the intake system, the engine management system can maintain optimal air-to-fuel ratios, promoting better fuel economy and overall drivability. While the performance gains from a CCV reroute alone may not be drastic, they become especially important when paired with other modifications such as intake upgrades, exhaust modifications, or tuning. 4. Extended Engine Life Oil mist and combustion byproducts recirculated into the intake not only lead to carbon buildup but can also cause damage to sensors and intake valves. Over time, the contaminated intake environment may lead to poor sensor readings, misfires, and even intake valve sticking. A rerouted CCV system mitigates these risks by ensuring that only clean air enters the intake tract, which contributes to smoother engine operation and longer service intervals. 5. Easier Maintenance and Reduced Downtime Cleaning out the intake system, turbocharger, or intercooler due to oil sludge buildup is time-consuming and expensive. Many diesel truck owners who do not address the root cause of this contamination find themselves performing this cleaning multiple times throughout the truck’s life. A CCV reroute greatly reduces the rate of oil vapor accumulation in these components. In many cases, owners who reroute their CCV system will not need to clean their intake or intercooler as frequently, leading to lower maintenance costs and more uptime on the road. Common Applications and Use Cases CCV reroutes are especially popular among diesel owners who use their trucks for high-load applications. These include: Heavy towing of trailers or equipment Off-road driving in dusty environments Performance or racing applications Long-distance hauling where engine longevity is critical In all of these cases, keeping the intake system clean and the turbocharger operating efficiently provides tangible benefits. For those seeking reliable engine ventilation upgrades, DynoVox offers precision-engineered CCV reroute kits for 6.7L Cummins, 6.7L Powerstroke, and 6.6L Duramax diesel engines. Designed for durability and performance, our kits reduce blow-by buildup and protect vital components. All products are stocked at DynoVoxParts.com with fast shipping, responsive support, and compatibility you can trust. DynoVox CCV PCV Reroute 2007-2023 6.7L Cummins CCV/PCV Reroute $59.99 $29.99 Shop Now 2004-2010 LLY LBZ LMM 6.6L Duramax CCV/PCV Reroute $99.99 $89.99 Shop Now 2011-2023 Ford 6.7L Powerstroke CCV/PCV Reroute $109.99 $79.99 Shop Now Are There Any Downsides? While a CCV reroute offers numerous advantages, there are a few considerations to keep in mind: 1. Emission Compliance In some regions, modifying or venting the CCV system to the atmosphere may not comply with emissions regulations. It is essential to verify the legality of a CCV reroute in your jurisdiction before proceeding with installation. 2. Proper Installation A poorly installed CCV reroute may result in oil leaks, pressure imbalance, or check engine lights. It is crucial to use high-quality fittings and hoses designed for the specific engine model, and to follow professional installation practices. 3. Vent Location and Catch Can Maintenance If using a catch can, it must be emptied periodically. Additionally, the reroute should vent in a clean and safe location that will not lead to environmental contamination or foul smells entering the cabin. Conclusion A CCV reroute is a highly effective modification for diesel engines, especially for those seeking improved reliability, better airflow, and reduced long-term maintenance. By redirecting oil vapors and blow-by gases away from the intake system, this upgrade helps preserve engine cleanliness, protect vital components, and promote more efficient combustion. For diesel truck owners who are serious about maintaining the performance and longevity of their engine, a CCV reroute represents a smart investment. When combined with regular maintenance and other complementary upgrades, this simple yet powerful modification can help your diesel engine run cleaner, longer, and stronger. FAQS 1. What are the benefits of a CCV reroute on a 6.7L Cummins? A CCV reroute reduces intake sludge, protects your turbo, and extends engine life by redirecting harmful oil vapors away from the intake system. 2. Does a CCV reroute improve fuel economy? Yes, by improving air quality entering the combustion chamber, a CCV reroute can contribute to cleaner burns and improved fuel efficiency. 3. How often should I clean my catch can after a CCV reroute? It is recommended to check and empty the catch can every 3,000 to 5,000 miles, depending on driving conditions and engine load. 4. Is a CCV delete legal for street use? In many regions, rerouting or deleting emissions-related systems may violate local regulations. Always verify your local laws before installation. 5. Does a CCV reroute affect turbocharger performance? Yes, it helps preserve turbocharger performance by preventing oil vapor buildup on the turbine and compressor fins. 6. Can I install a CCV reroute kit myself? Most CCV reroute kits are designed for DIY installation and include detailed instructions. Basic hand tools are typically all that is needed. 7. Will a CCV reroute trigger check engine lights? Properly installed reroute kits typically do not trigger codes, but it is important to use components designed specifically for your engine. 8. What materials are best for CCV reroute kits? High-quality kits use oil- and heat-resistant hoses, anodized aluminum fittings, and stainless steel clamps to ensure long-term reliability. 9. Is a catch can necessary with a CCV reroute? While not always required, a catch can adds an extra layer of protection by capturing oil mist and debris, further preventing intake contamination. 10. What trucks benefit most from a CCV reroute? Diesel trucks used for towing, long-haul driving, or heavy-duty work see the most noticeable improvements in intake cleanliness and performance.

The 6.7L Powerstroke engine represents a pinnacle of diesel engineering, balancing raw capability with stringent emissions compliance. Central to this equilibrium is the Crankcase Ventilation (CCV) system, designed to recirculate blow-by gases—a mixture of unburned fuel, exhaust, and oil vapors—back into the intake for combustion. While this reduces hydrocarbon emissions, it introduces mechanical compromises that frustrate many owners. Consequently, the CCV delete has emerged as a contentious modification. This analysis examines its technical rationale, benefits, risks, and implementation protocols, providing a roadmap for informed decision-making. Understanding the CCV System’s Role and Limitations The factory CCV system functions as an emissions-control device: 1. Gas Recirculation: Blow-by gases are routed from the crankcase to the intake manifold, where they mix with fresh air and reburn. 2. Contaminant Management: A filtration mechanism captures oil droplets and particulates, reducing oil ingestion into the combustion chamber. 3. Pressure Regulation: Maintains slight negative crankcase pressure to prevent oil leaks and seal damage. However, this design inherently restricts airflow, contaminates intake components with oil sludge, and increases turbocharger strain—issues magnified in high-load scenarios like towing. Differences Between CCV Delete and CCV Reroute Explained The CCV Delete removes the crankcase ventilation system entirely, venting gases externally and eliminating oil vapor from entering the intake. The CCV Reroute, however, redirects these gases away from the intake and into a catch can or atmospheric vent without full system removal. While both reduce carbon buildup and oil contamination, the delete offers more complete separation, whereas the reroute retains some factory function for emissions compliance in certain applications. The CCV Delete Explained: Mechanics and Variations A CCV delete modifies this system by rerouting blow-by gases away from the intake. Two primary approaches exist: Atmospheric Venting: Eliminates the CCV assembly entirely, venting gases directly to the environment via a hose. This maximizes airflow but risks environmental noncompliance. Reroute with Catch Can: Redirects gases to an external reservoir (catch can), trapping oil and contaminants before residual vapor exits. This balances performance with reduced emissions impact. Both methods aim to eliminate oil contamination within the intake system, reduce turbo backpressure, and simplify the overall architecture of the engine bay, leading to improved performance and easier maintenance. Evaluating the Pros of a CCV Delete 1. Enhanced Engine Performance and Longevity Unrestricted Airflow: Removing the CCV’s restrictive piping and filters improves volumetric efficiency, sharpening throttle response and combustion stability. Users report noticeable gains in turbo spool time and mid-range torque, particularly under load. Reduced Oil Contamination: By preventing oil-laden vapors from entering the intake, the delete mitigates carbon buildup on valves, intercoolers, and turbochargers. This preserves turbo efficiency and reduces risks of low-speed pre-ignition (LSPI). Turbocharger Protection: Oil accumulation in the charge-air cooler (CAC) diminishes heat dissipation. A delete minimizes this, extending turbo life and maintaining optimal charge temperatures. 2. Maintenance Simplification Eliminates clogged CCV filters (a known failure point on high-mileage engines). Reduces frequency of intake cleaning services. 3. Engine Bay Optimization Frees space for auxiliary components (e.g., aftermarket coolers, dual alternators) and eases access for repairs. Critical Cons and Risks 1. Legal and Environmental Implications Emissions Violations: Deleting the CCV system violates the U.S. Clean Air Act and Canadian environmental statutes for on-road vehicles. Penalties include fines up to $4,819 (EPA), registration revocation, or failed inspections in regulated states (e.g., California, New York). Environmental Impact: Atmospheric venting releases hydrocarbons and particulate matter directly into the air—estimated at 15–30% higher than stock systems. 2. Mechanical and Operational Drawbacks Increased Oil Consumption: Without recirculation, oil vapors escape into the atmosphere, necessitating more frequent top-offs (up to 1 quart per 3,000 miles). Crankcase Pressure Management: Poorly executed deletes may cause excessive crankcase pressure, forcing oil past seals and triggering leaks. This is especially prevalent in kits lacking vacuum-assist mechanisms like venturi tubes. Odor and Residue: Atmospheric vents emit a faint oil-burning smell during idle and may leave residue on the frame or exhaust. 3. Warranty and Reliability Concerns Voided powertrain coverage: Dealers may deny claims for turbo, engine, or emissions-related failures. Turboseal stress: Some technicians argue atmospheric venting disrupts factory pressure differentials, accelerating turbo-seal wear. Technical Insights: Why Design and Installation Matter Aggregated user data indicates that 70% of failures related to delete kits arise from either inadequate components or improper installation practices. Common issues include insufficient hose routing, which can cause oil pooling, and missing crankcase vacuum sources, leading to pressure buildup. Additionally, low-quality catch cans often overflow under high blow-by conditions. To mitigate these risks, it is essential to utilize venturi-style kits with optimized vacuum pressure, as they can reduce leak risks by 80% compared to traditional open vents, according to the Fleet Mechanic Report. Proper design and installation are crucial to ensuring the reliability and functionality of delete systems, ultimately enhancing the overall performance and longevity of the engine. The DynoVox Engineering Approach: Precision for Reliability For off-road or competition applications, DynoVox’s CCV reroute system addresses these challenges through: Venturi-Assisted Rerouting: Patented exhaust venturi tubes generate negative pressure to maintain crankcase vacuum, preventing oil leaks and pressure spikes. Baffled Catch Can Design: Multi-stage filtration separates 98% of oil aerosols, with CNC-machined ports eliminating spillage during hard acceleration. Emissions-Compliant Configuration: Optional closed-loop routing (with filtered atmospheric relief) minimizes environmental impact while retaining performance benefits. This integrated approach prioritizes durability over shortcuts—a necessity for engines operating beyond factory parameters. Installation and Long-Term Best Practices Professional Calibration: It is essential to pair the delete kit with professional ECU tuning to adjust airflow algorithms and prevent the illumination of check-engine lights. Routine Maintenance: To ensure optimal performance, you should drain the catch cans every 1,000 to 3,000 miles and monitor crankcase pressure using a manometer at least biannually. Additionally, it is important to inspect turbo seals during oil changes to catch any potential issues early. Legal Compliance: Always confirm local off-road exemptions, such as those for agricultural or racing use, and remember that venting unfiltered gases on public roads is prohibited. These best practices will help ensure the longevity and effectiveness of your delete system while maintaining compliance with applicable regulations. Conclusion: A Calculated Compromise The 6.7 Powerstroke CCV delete delivers tangible benefits: liberated airflow, reduced oil contamination, and simplified maintenance. However, it introduces legal liabilities, environmental trade-offs, and mechanical risks if implemented carelessly. For owners pursuing this path, DynoVox’s CCV Reroute systems offer a technically sophisticated middle ground—optimizing reliability while respecting ecological boundaries. Ultimately, the modification suits high-performance or off-road use cases where emissions compliance is secondary to mechanical integrity. In all scenarios, prioritize precision components and expert installation to avoid transforming a potential upgrade into an expensive regression. Disclaimer: CCV deletes violate emissions regulations for on-road vehicles in the U.S. and Canada. DynoVox designs these systems for sanctioned off-road/racing use only. Consult local laws before modification. FAQs 1. Will a CCV delete improve fuel economy? Marginal gains (0.5–1 MPG) are possible from reduced intake contamination, but airflow improvements alone rarely yield significant mileage increases. 2. Does CCV delete cause turbo failures? Poorly designed vents can increase seal stress, but vacuum-assisted reroutes (e.g., DynoVox’s venturi kits) mitigate this risk. 3. Can I revert to stock after a delete? Yes, but oil residue in the intake may require professional cleaning before reinstallation. 4. Is a catch can necessary for reroutes? Absolutely. Without filtration, rerouted gases deposit oil in unintended areas (e.g., frame rails, exhaust). 5. Why choose reroute over full delete? Reroutes maintain crankcase vacuum (preventing leaks) and reduce environmental impact—a ethical balance for conscientious owners. 6. What are the potential risks of a CCV delete? Risks include increased oil consumption, excessive crankcase pressure, and possible damage to engine seals or turbo components if improperly installed. 7. How often should I perform maintenance on a CCV delete system? It is recommended to drain catch cans every 1,000 to 3,000 miles and monitor crankcase pressure biannually. 8. What is the difference between a CCV delete and CCV reroute? A CCV delete completely removes the CCV system, venting gases to the atmosphere, while a CCV reroute directs gases to a catch can to trap contaminants. 9. Can I install a CCV delete kit myself? While some experienced users may attempt a DIY installation, it is advisable to have it professionally installed to ensure optimal performance and reduce risks. 10. What should I do if my CCV delete system causes issues? If you encounter problems, it’s essential to consult a professional mechanic who can assess the installation and components used, ensuring they meet performance expectations and compliance standards.

This article primarily discusses the benefits of a CCV Reroute and offers guidance on how to select a suitable CCV Reroute. It explains the advantages such as reducing oil contamination and improving engine performance, while also providing tips on choosing the right kit based on factors like quality, compatibility, and maintenance needs.

Aug 09, 2025

Aug 07, 2025

Aug 01, 2025