What Does an EGR ...

Aug 09, 2025

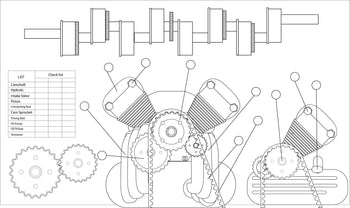

The crankcase ventilation (CCV) system on the 6.7L Cummins plays a vital role in managing blow-by gases and maintaining proper crankcase pressure. However, the factory design often results in excessive pressure build-up, oil consumption and turbo contamination. This article details actual pressure testing of a stock CCV system, identifies key restriction points, and explains why CCV redirection or PCV redirection is often necessary for optimal engine performance and longevity. Why Test CCV System Pressure? Excessive crankcase pressure can cause: · Oil leaks (seals, gaskets, turbo feed lines) · Increased oil consumption (blow-by carrying oil into intake) · Turbocharger contamination (oil coking on compressor wheel) · Reduced engine efficiency (higher crankcase pressure = more parasitic loss) By measuring pressure at different points in the system, we can pinpoint where restrictions occur and determine the best solution—whether that’s a CCV reroute kit, a catch can, or a complete redesign. Testing Methodology We conducted pressure tests on a stock 6.7L Cummins using: · Digital manometer (measuring in inches of water column, "H₂O) · Pressure taps at critical locations: o Valve cover outlet (pre-CCV restriction) o Post-CCV hose (before turbo inlet) o Crankcase dipstick tube (baseline pressure) Tests were performed at:✔ Idle (700 RPM)✔ Mid-load (2,000 RPM, light throttle)✔ High-load (WOT, 3,000+ RPM) Key Findings: Where the Stock CCV System Fails 1. Excessive Crankcase Pressure at Higher RPM · Idle: ~1.5" H₂O (acceptable) · 2,000 RPM: ~4.2" H₂O (approaching problematic) · WOT: 8-10" H₂O (far beyond ideal) Why It Matters: · Pressures above 4-5" H₂O can force oil past seals and into the intake. · At WOT, the stock system cannot evacuate blow-by efficiently. 2. Major Restriction: Factory CCV "Rooster Comb" Baffle The stock Cummins CCV system uses a "rooster comb" baffle inside the valve cover to separate oil from blow-by gases. Testing revealed: · Pressure drop across baffle: ~3.5" H₂O at high RPM · Oil carryover: Significant mist still reaches the turbo inlet Problem: The factory baffle is too restrictive and doesn’t separate oil effectively. 3. Turbo Inlet Contamination Risk · Post-CCV testing showed oil mist accumulation in the intake piping. · Over time, this leads to turbo coking and intercooler clogging. The Solution: CCV Reroute or Performance Baffle Upgrade Since the stock system is restrictive and inefficient, there are two proven fixes: Option 1: Full CCV Reroute (Vented or Catch Can) · Eliminates intake contamination by venting to atmosphere or a catch can. · Reduces crankcase pressure to safe levels (<3" H₂O at all RPMs). · Best for modified/high-performance engines where blow-by is increased. Option 2: High-Flow Baffle Upgrade · Replaces restrictive "rooster comb" with a better-flowing design. · Improves oil separation while maintaining emissions compliance. · Good for stock/near-stock trucks where rerouting isn’t desired. Performance Gains from a Proper CCV Solution ✔ Reduced oil consumption (less blow-by oil loss)✔ Cleaner turbo & intercooler (no more oil coking)✔ Longer engine life (less pressure on seals/gaskets)✔ Better throttle response (reduced crankcase pumping losses) Upgrade Your CCV System Today If your 6.7L Cummins is suffering from excessive crankcase pressure or oil consumption, a CCV reroute kit is the proven solution. Check out our high-performance CCV/PCV Reroute Kits to optimize your engine’s breathing and reliability.

The crankcase ventilation (CCV) system, also known as the positive crankcase ventilation (PCV) system, plays a vital role in maintaining engine health by managing blow-by gases. However, poor design can result in excessive oil consumption, turbo contamination and reduced engine efficiency. This article explores how Venturi effect dynamics and baffle engineering affect oil separation, and how CCV redirection or PCV redirection can optimize performance in modern diesel engines. The Role of the CCV/PCV System The CCV system prevents pressure build-up in the crankcase by rerouting blow-by gases back into the intake for combustion. However, if these gases are not properly controlled they can lead to oil mist, which: · Coat turbocharger wheels, reducing efficiency · Clog intercoolers, increasing intake air temperatures · Contaminate sensors, causing drivability issues Venturi Effect: How It Enhances Oil Separation Many high-performance CCV systems take advantage of the Venturi effect – a fluid dynamics principle in which the velocity of a gas increases as it passes through a constricted section, causing a reduction in pressure. Key Benefits of Venturi-Based CCV Systems Improved Oil Mist Capture – The low-pressure zone helps separate oil droplets from blow-by gases.Reduced Turbo Contamination – Less oil ingestion means cleaner compressor wheels and intercoolersLower Crankcase Pressure – Efficient evacuation minimizes oil leaks and seal failures. Baffle Design: The Unsung Hero of Oil Separation An effective baffle system inside the valve cover or CCV housing ensures that oil droplets are trapped before entering the intake. Critical Baffle Design Features · Multi-Stage Filtration – Mesh screens, centrifugal separators, and impact surfaces maximize oil capture. · Drainback Channels – Collected oil must return efficiently to the crankcase to prevent pooling. · Heat Resistance – High-quality materials prevent warping under extreme temperatures. Why a CCV Reroute or PCV Reroute is Often Necessary Factory CCV systems are often undersized or poorly routed, leading to: · Excessive oil consumption · Turbo oil coking · EGR and intake clogging A high-quality CCV reroute kit solves these issues by:Relocating the vent path (e.g., to atmosphere or a catch can)Incorporating advanced baffling for superior oil separationReducing intake tract contamination Performance & Longevity Benefits of an Optimized CCV System · Cleaner Turbo & Intercooler – Prevents oil buildup that restricts airflow. · Stable Crankcase Pressure – Reduces risk of leaks and seal failures. · Improved Engine Efficiency – Less oil burn means better combustion consistency. Upgrade Your CCV System Today If your engine suffers from excessive oil consumption or turbo contamination, a PCV/CCV reroute could be the solution. Check out our selection of high-performance CCV/PCV Reroute Kits to optimize your engine’s breathing.

The 6.7L Cummins engine has earned its reputation as one of the most durable and high-performing diesel platforms available on the market. Its widespread use in heavy-duty Ram trucks has made it a staple among fleet operators, towing professionals, and performance enthusiasts. While its core mechanical architecture is robust, certain emissions-related subsystems—such as the factory Crankcase Ventilation (CCV) system—pose long-term risks to engine efficiency, cleanliness, and operational stability. One often overlooked modification that has a measurable impact on the 6.7L Cummins is the CCV reroute. While not as attention-grabbing as performance tuners or turbo upgrades, the rerouting of crankcase gases offers tangible, long-term benefits that directly affect engine longevity and operational precision. This article explores the intricate role of the CCV system, the limitations of its stock configuration, and the multi-dimensional advantages of a properly engineered reroute. Understanding the Function of the CCV System The CCV system, or Crankcase Ventilation system, is designed to manage the blow-by gases generated during the combustion cycle. As pressure builds within the crankcase due to minor combustion leakage past piston rings, it becomes necessary to vent these gases to maintain pressure equilibrium and prevent oil seal damage. In the stock 6.7L Cummins configuration, these crankcase gases—laden with oil mist and unburned hydrocarbons—are rerouted back into the intake tract. This method is implemented primarily for emissions control, as it allows the vapors to be reburned during combustion. However, while effective for meeting EPA regulations, this solution introduces a host of mechanical inefficiencies and contamination risks. Hidden Consequences of Recirculating Blow-By Gases The gases expelled from the crankcase are not inert. They are a complex mixture of oil vapor, fuel residues, combustion byproducts, and moisture. When these elements are routed back into the intake system, several issues begin to manifest: Oil Film Accumulation: Thin layers of oil coat the intake piping, throttle valve, and intercooler. This not only restricts airflow but also creates a sticky substrate for dust and soot particles to adhere to. Carbon Build-Up: In engines that also utilize an Exhaust Gas Recirculation (EGR) system, the combination of soot and oil mist leads to hardened carbon buildup. This drastically reduces volumetric efficiency and can choke airflow through the intake manifold. Sensor Contamination: Mass airflow sensors, MAP sensors, and throttle actuators are prone to failure when subjected to prolonged oil vapor exposure. Turbo Efficiency Loss: The turbocharger’s compressor wheel is particularly sensitive to oil vapor. Coating the fins with residue affects balance, spool rate, and long-term bearing health. While these consequences do not immediately disable the engine, their cumulative effect is a gradual but persistent degradation in performance, fuel economy, and reliability. How a CCV Reroute Solves These Issues A CCV reroute addresses the above concerns by redirecting crankcase gases away from the intake system and venting them through a separate, filtered outlet—often externally. This modification, though conceptually simple, has profound effects on engine cleanliness and stability. 1. Preserves Intake System Integrity The removal of oil-laden gases from the intake pathway ensures that no film or residue builds up over time. This helps maintain consistent airflow velocity, preserve sensor accuracy, and prevent premature failure of throttle bodies or EGR components. In practical terms, the engine breathes cleaner air, combustion is more stable, and the intake components remain cleaner even after tens of thousands of miles. 2. Reduces Turbocharger Contamination By preventing oil vapor from reaching the turbo inlet, a CCV reroute safeguards one of the engine’s most expensive and sensitive components. A clean compressor wheel maintains its aerodynamic properties, ensuring that turbo boost levels remain consistent and efficient. This is particularly crucial for engines subjected to high-load applications like towing or high-altitude driving. 3. Lowers Maintenance Costs and Intervals Contaminated intercoolers, fouled sensors, and EGR-related service are common and costly. A CCV reroute significantly delays, and in many cases eliminates, the need for such service. This translates to longer intervals between deep cleanings, fewer diagnostic issues, and more predictable maintenance planning for owners. 4. Improves Engine Longevity Through Cleaner Combustion Cleaner intake air leads to more complete combustion, especially under high cylinder pressures. The removal of oil mist eliminates the risk of pre-ignition caused by volatile hydrocarbons entering the combustion chamber. Over time, this helps preserve piston ring sealing integrity, cylinder wall condition, and oil quality—each of which contributes to engine life. 5. Minimizes Regeneration Frequency in DPF-Equipped Engines Though indirect, one valuable benefit of a CCV reroute is the reduction in particulate matter entering the exhaust system. When oil is burned alongside diesel fuel due to crankcase vapor recirculation, it produces more soot, which accelerates the clogging of the diesel particulate filter (DPF). Cleaner combustion means fewer regeneration cycles and extended DPF service intervals. Recommended Product: DynoVox 6.7L Cummins CCV/PCV Reroute Kit For 2007–2023 Dodge Ram owners seeking to eliminate oil mist buildup and protect turbo efficiency, the DynoVox CCV/PCV Reroute Kit is a reliable solution. Designed specifically for the 6.7L Cummins, it improves engine ventilation, reduces carbon deposits, and supports long-term performance. Easy to install and built to last. Shop the 6.7L Cummins CCV Reroute Kit Now Technical Considerations Before Implementation While the advantages are compelling, it is important to ensure that the reroute is done correctly. Improper venting may allow moisture or oil to pool around the engine bay. In colder climates, expelled vapors can condense and freeze, causing blockages if not properly filtered or routed downward. Therefore, any CCV reroute should be accompanied by a high-quality filter or catch-can system and be designed to prevent backpressure. Additionally, reroutes may be subject to regulatory scrutiny in some jurisdictions. As with any emissions-related modification, vehicle owners must ensure that they remain compliant with local laws if the truck is intended for on-road use. Conclusion The 6.7L Cummins engine is a highly capable and respected platform, but its factory CCV system introduces vulnerabilities that can compromise performance and increase maintenance costs over time. By implementing a CCV reroute, owners can proactively protect critical components such as the turbocharger, intake manifold, and intercooler. This single modification offers a layered benefit structure—improving engine hygiene, stabilizing combustion quality, and reducing service frequency. When viewed from a long-term ownership perspective, the CCV reroute is not just a niche upgrade; it is a calculated step toward preserving mechanical integrity and maximizing return on investment in a diesel engine platform. For those seeking to optimize every aspect of their 6.7L Cummins engine—from throttle response to overall system cleanliness—the CCV reroute is not optional. It is essential. Frequently Asked Questions (FAQs) 1. What does a CCV system do on a 6.7L Cummins engine?The CCV system (Crankcase Ventilation) routes blow-by gases from the crankcase back into the intake, reducing emissions but potentially introducing oil vapor into the air intake system. 2. Why should I consider a CCV reroute for my 6.7L Cummins?A CCV reroute helps prevent oil vapor from contaminating the intake manifold and turbocharger, reducing carbon buildup and improving long-term engine reliability. 3. Does a CCV reroute improve fuel economy on the 6.7L Cummins?Yes, many drivers notice slight improvements in fuel economy due to cleaner combustion and more efficient turbo operation after installing a CCV reroute. 4. Will a CCV reroute lower maintenance costs?Absolutely. By keeping oil out of the intake and turbo system, a CCV reroute can help extend the life of key components and reduce the need for frequent cleaning or part replacement. 5. Is a CCV reroute legal for on-road use?Legality varies by region. While CCV reroutes are often used for off-road or racing applications, users should verify compliance with local emissions regulations. 6. Can I install a CCV reroute kit myself on a 6.7L Cummins?Yes, most CCV reroute kits are designed for DIY installation with basic tools. However, professional installation is recommended if you're unfamiliar with engine components. 7. What are the signs that I need a CCV reroute?Excessive oil in the intercooler piping, sluggish turbo response, or visible oil vapor in the intake system are common signs indicating the need for a reroute. 8. Does a CCV reroute affect engine warranty?Modifying the CCV system may affect your engine warranty. It is important to check with your manufacturer or dealer before performing any modifications. 9. How often should I service a CCV reroute system?Unlike the factory CCV setup, reroute systems generally require less maintenance. Occasional inspection of hoses and fittings is sufficient for most setups. 10. Will a CCV reroute improve engine performance on its own?While it may not drastically increase horsepower, a CCV reroute enhances performance by improving airflow efficiency and protecting the turbo from oil-related issues.

Learn how a 6.7L Cummins CCV reroute kit improves engine performance, reduces oil buildup, and extends turbo life. Includes installation tips & FAQs.

Aug 09, 2025

Aug 07, 2025

Aug 01, 2025